Cocoa with purpose:

Our mission-driven approach

The St Vincent Cocoa Company (SVCC) is 100% Vincentian, registered in St Vincent, operated by Vincentians and employing Vincentians. SVCC is the only cocoa Company operating in St Vincent.

We are creating a cocoa industry in St Vincent because it has nigh on perfect conditions for cocoa production. As well as building a great business, we firmly believe that we can make a real difference to the lives of many Vincentians.

Growing, processing and exporting premium cocoa to very exact and strict criteria is a meticulous process requiring significant resources and logistical standards and this goes hand in hand with doing this in the right way; sustainably and ethically.

COMPANY FARMS

Pictured: David Hull (Agricultural Worker) picking cocoa pods with a pruning share.

We operate on approximately 700 acres, of which 60% are owned by the company and the remainder is leased. The majority of these lands had been left idle for years after banana farming ceased to be profitable.

During the initialization of the company we took cuttings from the best ‘mother’ trees in St Vincent and with additional stock from the International Cocoa Centre, we established a gene bank to form the bedrock of our stock - as a result we have an impressive collection of genetic varieties, carefully curated and stored in our state-of-the-art Gene Bank.

In close proximity to our Gene Bank is our Nursery, where young cocoa plants are grown and grafted before they are taken out to the mountains for planting.

LOCAL FARMERS

Pictured: Harvey Butler, Local Cocoa Farmer.

In the 1950s and 1960s, cocoa was widely grown in St. Vincent before bananas. Most of the root stock was imported from Trinidad, where the Trinitario cocoa variety was developed. Today, the company buys cocoa from local farmers who continue to grow this cocoa. This benefits the farmers as most are now subsistence farmers with limited access to regional/international markets. Additionally, the company buys cocoa to supplement its own supplies. As the company's yield grows, it continues to buy from farmers as their cocoa is integral to achieving our goals.

From processing to perfection: How our company brings you the finest cocoa products

All the cocoa we produce is processed by us, including what we buy in from local farmers. This takes place at our purpose-built facility at Perseverance, near Georgetown, which is on the North-east coast.

Each week, the following takes place:

Ripe pods are hand-picked from trees

These pods are split, and the cacao beans taken same day to Perseverance

The husks are left on the Farms, composted and used later as organic fertilizer

Beans are fermented for about a week during which time the flavour of chocolate develops.

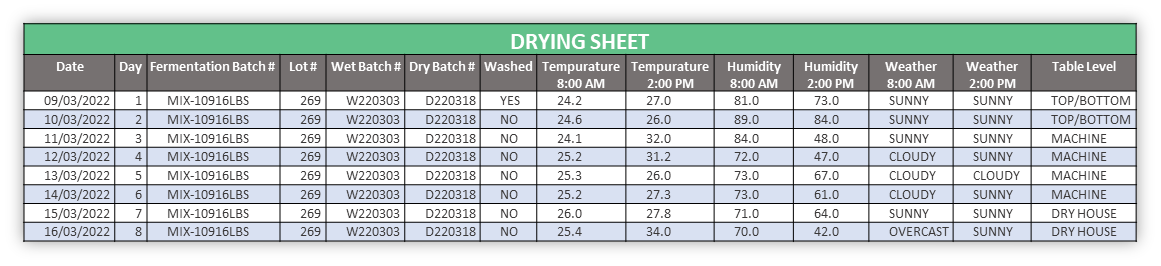

Drying takes place in our solar driers.

After a two-day period to allow the cocoa to cool off and its moisture content to stabilize before it is bagged up and stored in our temperature-controlled building.